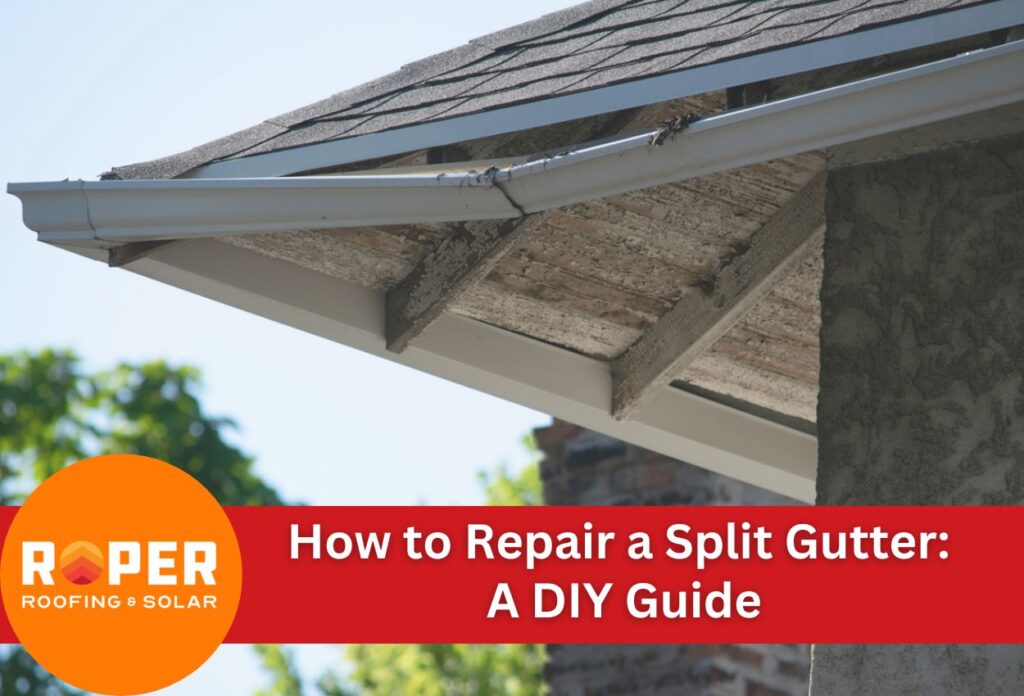

Split gutters pose a serious threat to your home’s foundation and exterior walls. When gutters crack or develop gaps, water escapes and flows directly against your house instead of being properly channeled away. This seemingly minor issue quickly escalates into expensive problems, including foundation damage, basement flooding, and exterior wall deterioration.

Several factors contribute to a gutter splitting and cracking. Weather damage from Denver’s harsh winters and intense summer heat cycles causes aluminum gutters to expand and contract repeatedly. Age naturally weakens gutter materials, making them more susceptible to stress fractures. Improper installation creates weak points where gutters cannot handle normal water flow and debris loads. Poor maintenance allows small cracks to grow into major splits that require immediate attention.

Repairing gutter cracks and fixing damaged gutters becomes urgent once water damage begins. Acting quickly when you notice split gutters prevents expensive repairs to your roof, siding, and foundation. Modern gutter sealing methods and aluminum gutter repair techniques allow homeowners to address these problems effectively. Understanding proper repair approaches helps you determine whether repairing split gutters falls within your capabilities or requires professional intervention.

The Tools and Materials for Cracked Gutter Repairs

Successful aluminum gutter repair requires specific tools and materials designed for repairing gutter cracks effectively. Basic safety equipment forms the foundation of any repair project, including sturdy ladders, non-slip shoes, and work gloves to prevent injuries during the repair process. Wire brushes and paint scrapers remove debris, rust, and old sealant from damaged areas, ensuring proper adhesion of new repair materials.

Gutter sealing methods depend heavily on choosing appropriate materials for the type of damage. Roofing cement works well for small cracks and minor splits in aluminum gutters. These products create waterproof seals that expand and contract with temperature changes. For larger gaps, fiberglass mesh patches combined with roofing cement provide reinforced repairs that handle structural stress better than sealant alone.

Fixing damaged gutters often requires specialized products like gutter sealant tubes, which apply easily with standard caulking guns. Aluminum repair tape offers another solution for repairing split gutters, particularly when dealing with linear cracks along gutter seams. This tape bonds directly to clean aluminum surfaces and creates lasting waterproof barriers.

Professional-grade options include two-part epoxy compounds specifically formulated for metal repairs. These products cure to form permanent bonds stronger than the original gutter material, making them ideal for high-stress areas where traditional sealants might fail over time.

Safety First: Preparing Your Workspace for Gutter Repairs

Proper preparation ensures successful gutter sealing methods while preventing dangerous accidents during aluminum gutter repair projects. Ladder safety forms the most critical aspect of repairing split gutters, as most injuries occur from falls rather than the repair work itself.

Weather conditions directly impact both safety and repair quality when fixing damaged gutters. Avoid repairing gutter cracks during windy conditions, as gusts can destabilize ladders and make precise work impossible. Rain or high humidity prevents the sealants from properly bonding to the repair materials, leading to failed repairs that require redoing the entire project. Temperature extremes also affect material performance, with many gutter repair products requiring temperatures between 50 and 85 degrees Fahrenheit for curing.

Clearing debris from split gutters creates clean surfaces essential for lasting repairs. Remove all leaves, twigs, and accumulated dirt from the damaged area using wire brushes and scrapers. Rinse the section thoroughly with water and allow complete drying before applying any sealing materials. Clean aluminum surfaces allow repair products to bond properly, ensuring the fix withstands normal water flow and weather exposure. This preparation step often determines whether repairs last for years or fail within months of completion.

The Process for Sealing Small Gutter Cracks

Cleaning and preparing minor cracks in aluminum gutters requires thorough attention to detail for achieving long-lasting repairs. Begin by removing all debris, dirt, and loose material from the cracked area using a wire brush or paint scraper. This initial cleaning exposes the full extent of damage and reveals whether the crack extends beyond what appears visible on the surface. Scrub the damaged section with a stiff brush to remove oxidation, old paint, and accumulated grime that prevents proper adhesion of repair materials.

Surface preparation techniques for repairing gutter cracks involve creating clean, slightly rough surfaces that allow sealing compounds to bond effectively. Sand the area around small splits using medium-grit sandpaper, focusing on removing any smooth or glossy surfaces. Clean the sanded area with rubbing alcohol or acetone to eliminate oils and residue that interfere with repair materials. Allow the surface to dry completely before proceeding with actual repairs, as moisture trapped under sealants causes premature failure.

Application methods for gutter sealing compounds vary based on crack size and chosen repair materials. Apply roofing cement or specialized gutter sealant in thin, even layers using a putty knife or similar tool. Work the material into the crack thoroughly, ensuring complete coverage without creating thick buildup that restricts water flow. For aluminum gutter repair projects involving slightly larger cracks, embed fiberglass mesh into the first layer of sealant before applying a second coat for reinforcement.

Smooth the repair area carefully to maintain proper water flow characteristics while preventing future leaks. Remove excess material and create slight slopes that direct water toward downspouts rather than allowing pooling near repaired sections.

Repairing Larger Splits with Patching Techniques

Extensive gutter damage requires more robust repair methods than simple sealants can provide. Measuring and cutting patches for bigger splits begins with accurately determining the damaged area dimensions. Mark the damaged section with at least 1 inch of overlap on all sides to ensure complete coverage. Create a paper template first, then trace this pattern onto your patch material for precise cuts. Use tin snips for aluminum patches or heavy scissors for fiberglass materials, ensuring clean edges that lie flat against the gutter surface.

Selecting appropriate patch materials depends on your existing gutter system composition and the severity of damage. Aluminum patches work best for fixing damaged gutters made of the same material, as they expand and contract at matching rates. Fiberglass patches offer versatility for different gutter types and provide excellent flexibility for repairing gutter cracks that span corners or curved sections. Rubber membrane patches excel in areas with significant movement or where traditional rigid materials might fail.

Installation procedures for aluminum gutter repair patches require careful attention to adhesion and mechanical fastening. Apply roofing cement or specialized gutter adhesive to both the damaged gutter and patch surfaces, creating complete coverage without excess buildup. Position the patch carefully and press firmly to eliminate air bubbles that compromise waterproof seals.

Weatherproofing techniques ensure patched repairs withstand temperature fluctuations and moisture exposure. Apply additional sealant around patch edges, feathering the material to create smooth transitions that prevent water pooling. Allow proper curing time before exposing repairs to water flow.

Testing Your Repair and Preventing Future Damage

Proper testing methods ensure your gutter sealing methods create watertight repairs that withstand heavy rainfall and snowmelt. Begin testing by running a garden hose along the repaired section at low pressure, gradually increasing water flow to simulate moderate rain conditions. Watch carefully for any seepage around the repair area, paying special attention to edges where new sealant meets existing aluminum surfaces. Allow water to flow for at least 15 minutes during initial testing to verify the repair maintains integrity under sustained water exposure.

Advanced testing procedures for aluminum gutter repair involve simulating severe weather conditions that challenge repaired sections. Fill the gutter section with standing water to test for slow leaks that might not appear during flowing water tests. This static water test reveals pinhole leaks or inadequate sealing that normal flow testing might miss. Check underneath the repair area after 30 minutes of standing water to confirm no moisture appears on the exterior of the gutter.

Preventive maintenance significantly extends gutter life and reduces the frequency of gutter cracks. Schedule quarterly gutter cleaning to remove debris that causes standing water and accelerated corrosion. During each cleaning, inspect all seams, joints, and previously repaired areas for signs of new splits or failing sealants.

Regular inspection routines help identify potential problems before they cause water damage. Check gutters after major storms for new stress cracks or loose sections that need attention. Properly maintained gutters last significantly longer than neglected systems.

When to Call Professional Gutter Contractors

Recognizing when gutter damage exceeds DIY repair capabilities prevents homeowners from attempting fixes that may worsen existing problems. Structural damage to fascia boards or rafter ends requires professional assessment, as these issues involve more than simple gutter sealing methods. When aluminum gutter repair involves extensive sections spanning multiple joints or corners, professional contractors possess the specialized equipment and experience necessary for lasting solutions. Large splits extending beyond 12 inches typically indicate underlying structural problems that DIY approaches cannot address effectively.

Safety concerns also warrant professional intervention when repairing gutter cracks. Multi-story homes or steep roof angles create dangerous working conditions that increase fall risks significantly. Professional contractors carry proper insurance and safety equipment designed for challenging installations. Additionally, when fixing damaged gutters requires removing sections or realigning hangers, professional expertise ensures proper drainage slopes and structural integrity.

Reputable professionals provide detailed estimates explaining repair methods and materials before beginning work. They should demonstrate familiarity with local building codes and weather conditions that affect repair longevity. Quality contractors also offer warranties on their work, assuring that repairs will withstand normal weather exposure.

Professional services become essential when repairing split gutters involves coordinating with roofing repairs or when damage indicates problems with home drainage systems. Experienced contractors can identify underlying causes contributing to gutter failure and recommend comprehensive solutions that prevent recurring issues.

Denver’s Top Choice for Professional Gutter Repair: Roper Roofing & Solar

If you’ve tried all DIY methods and your gutters are still leaking or damaged, it might be time to call in the professionals. At Roper Roofing & Solar, we specialize in repairing and sealing all types of gutter splits and cracks, ensuring your home is protected from water damage.

Don’t let small issues turn into expensive repairs. Act now and ensure your gutters are in top condition to withstand Denver’s harsh weather conditions. Call us today at (720) 475-1065 for a consultation and let us help you maintain the integrity of your home’s exterior efficiently and effectively.