Key Points About Preparing For a Slate Roof Installation

- Proper slate roof installation prep requires structural evaluation since slate weighs up to 700 pounds per square.

- Roof deck preparation involves cleaning, spacing boards 1/8 inch apart, and securing with ring shank nails.

- Quality underlayment installation with 4-inch horizontal and 6-inch vertical overlaps prevents water infiltration under slate tiles.

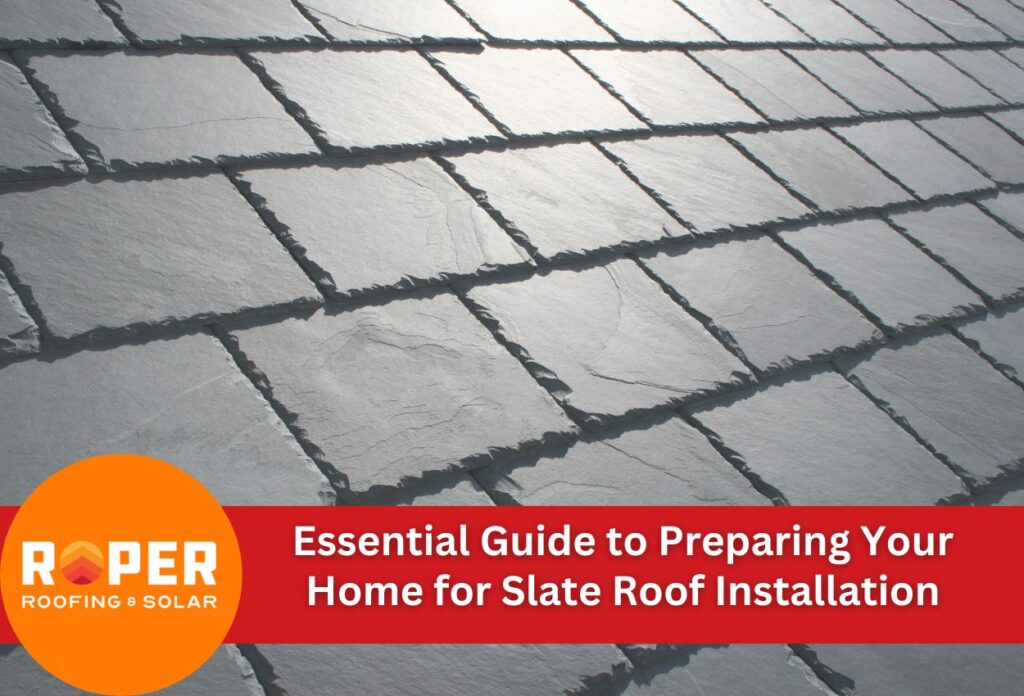

Slate roofing materials offer exceptional durability and timeless beauty, but successful installation depends entirely on thorough preparation before the first tile touches your roof deck. Proper slate roof installation prep protects your investment and ensures decades of reliable performance from your new roofing system.

The foundation of any slate roof begins with meticulous roof deck preparation. The existing structure must support the substantial weight of slate tiles, which can weigh up to 700 pounds per square compared to standard asphalt shingles. Structural engineers often evaluate the roof framing to confirm adequate support capacity before installation begins.

Underlayment installation represents another important preparation phase that directly impacts its long-term performance. Quality underlayment creates a secondary barrier against moisture while allowing the slate tiles to breathe properly. This protective layer must meet specific requirements to prevent premature failure and warranty issues.

Professional roofing contractor preparation involves coordinating multiple trades, securing proper permits, and establishing clear timelines for each phase of work. Homeowners who understand these preparation phases can make informed decisions and avoid expensive mistakes that compromise their slate roof investment. The preparation process sets the stage for installation success and determines whether your slate roof will perform reliably for generations.

Selecting the Right Materials and Tiles for Your Project

Choosing the appropriate slate roofing materials requires considering several key factors that impact both performance and appearance. Natural slate tiles vary significantly in composition, color, and durability characteristics depending on the quarry they originate from and how the slate was formed.

Welsh slate offers great density and weather resistance, making it ideal for harsh climate conditions, while Vermont slate provides excellent color consistency and moderate pricing. Spanish slate delivers cost-effective options with good performance characteristics for most residential applications. Each type of slate responds differently to freeze-thaw cycles, making material selection important for long-term roof deck preparation success.

Understanding the grades of slate tile can help property owners make informed decisions about quality and longevity. Thickness requirements typically range from 3/16 inch for standard applications to ¼ inch for premium installations requiring maximum durability.

The quality of a tile can be seen through consistent thickness throughout each tile, clean break lines, and the absence of soft spots or mineral inclusions that could compromise performance. Professional slate tile requirements also specify proper nail hole placement and edge preparation to ensure secure attachment during installation. These material considerations directly influence underlayment installation requirements and overall roofing contractor preparation processes, making proper selection essential for project success.

Preparing Your Roof Deck for Slate Installation

Creating a solid foundation begins with thorough preparation work to the roof deck that addresses the structural integrity and surface conditions. The existing deck must be completely clean, dry, and free from any debris, old roofing materials, or protruding nails that could compromise the installation. Professional contractors inspect each deck board for signs of rot, warping, or damage that requires repair before proceeding.

Proper spacing between decking materials allows for expansion and contraction cycles while maintaining adequate support for heavy slate tiles. Decking boards should be spaced approximately ⅛ inch apart to accommodate seasonal movement without creating gaps that will affect the stability of the tiles. This spacing requirement becomes particularly important during slate roof installation prep in areas with significant temperature fluctuations.

Fastening requirements for roof decking materials require specific attention to nail placement and depth. Each board must be secured with appropriate fasteners that go through to the roof rafters by at least 1½ inches. Ring shank nails also provide superior holding power compared to standard smooth nails, reducing the risk of deck movement over time.

Surface preparation includes addressing any high spots or depressions that could affect the installation of the underlayment. A properly prepared deck creates uniform support across the entire surface of the roof, preventing stress points that lead to premature tile failure. Roofing contractor preparation standards require deck surfaces to meet strict flatness tolerances before the installation of slate materials begins.

Installing Quality Underlayment Systems

Quality underlayment is the critical barrier between slate tiles and the roof’s deck, protecting against leaks while managing moisture/vapor transmission. Ice and water shields represent the premium choice for slate roofing applications, providing self-sealing properties around nail holes and adhesion to the surface of the deck. This rubberized membrane creates a barrier in vulnerable areas like valleys, eaves, and rake edges where water accumulation poses the greatest risk.

Synthetic underlayment offers excellent durability and tear resistance for slate installations, withstanding foot traffic during construction phases better than traditional felt materials. The lightweight composition reduces installation time while providing enhanced UV protection during extended exposure. Premium synthetic options also include slip-resistant surfaces that improve worker safety during the installation.

Proper installation requires specific overlap measurements to ensure complete coverage without gaps. Horizontal overlaps must extend at least 4 inches, while vertical seams require 6-inch overlaps to prevent leaks. Side laps should be sealed with plastic cement or approved adhesive to create watertight connections between underlayment sections.

Sealing methods around roof gaps require careful attention to detail and proper material selection. Vent pipes, chimneys, and other protrusions require underlayment to extend at least 6 inches beyond the gaps on all sides. Boots and step flashing integration must occur during the installation of underlayment to maintain the continuous moisture barrier essential for long-term slate tile performance and the integrity of the system.

Planning for Flashing and Ventilation Components

Proper flashing installation must occur before the actual roof installation begins to ensure water-tight seals around important roof gaps and transitions. Step flashing around chimneys requires individual pieces that interweave with each course of slate tiles, creating a continuous barrier that directs water away from vulnerable joints. Valley flashing systems require wide metal channels that extend at least 8 inches up each roof slope to handle heavy water volumes during storms.

Roof edge flashing protects the most exposed areas where wind-driven rain can get beneath slate roofing materials. Drip edge installation along eaves and rakes creates clean water runoff while supporting the first course of slate tiles. These components must be fabricated from compatible metals that resist corrosion when in contact with slate fasteners and clips.

Ventilation planning addresses both intake and exhaust airflow requirements that prevent moisture buildup within the roof assembly. Ridge vents provide continuous exhaust along the peak of the roof, while soffit vents supply fresh air intake at the eaves. This balanced ventilation system protects both the roof deck preparation work and slate tile installation by maintaining proper temperature and humidity levels.

Roofing contractor preparation includes calculating proper ventilation ratios based on attic square footage and local climate conditions. Inadequate ventilation leads to ice dam formation, condensation problems, and premature deterioration of both underlayment and structural components.

Preparing Your Property and Coordinating with Professional Contractors

Preparation is important for a successful slate roof installation. Covering delicate plants, removing outdoor furniture, and protecting walkways prevent damage from falling debris during the roofing process. Establishing clear pathways for material delivery ensures efficient workflow while minimizing impact on existing landscape features.

Access considerations include evaluating the best routes for transporting heavy slate roofing materials to the work area. Professional contractors require adequate space for equipment positioning, including scaffolding systems and material hoists necessary for safe slate tile handling. Driveway protection using plywood or other barrier materials prevents damage from heavy trucks delivering roofing supplies.

Effective coordination with roofing contractors begins with understanding their preparation requirements and timeline expectations. Key questions should address how they handle roof deck preparation, what specific underlayment installation methods they use, and their experience with local building permit requirements.

Communication protocols establish clear expectations for daily work schedules, cleanup procedures, and weather contingency plans. Professional roofing contractor preparation includes securing necessary permits, arranging material deliveries, and coordinating with other trades when additional structural work becomes necessary. Property owners benefit from understanding these coordination efforts to ensure smooth project execution and minimize disruptions to daily routines.

Denver’s Premier Slate Roof Installation Services

Are you preparing for your new slate roof installation? Ensure your home receives the best care and expertise by choosing Roper Roofing & Solar. Our experienced team specializes in all aspects of slate roof installation prep, from assessing your current roof structure to selecting the highest quality slate materials that match your appearance and budget needs.

Ready to start your slate roof transformation? Call us now at (720) 475-1065 and take the first step towards a durable and beautifully installed slate roof. Roper Roofing & Solar is your trusted partner in Denver for all your roofing needs.